APWT Auto-Purger

The AP Refresh (APWT) AUTO-PURGER offers many new features with the same reliability as the original AUTO-PURGER. New features include:

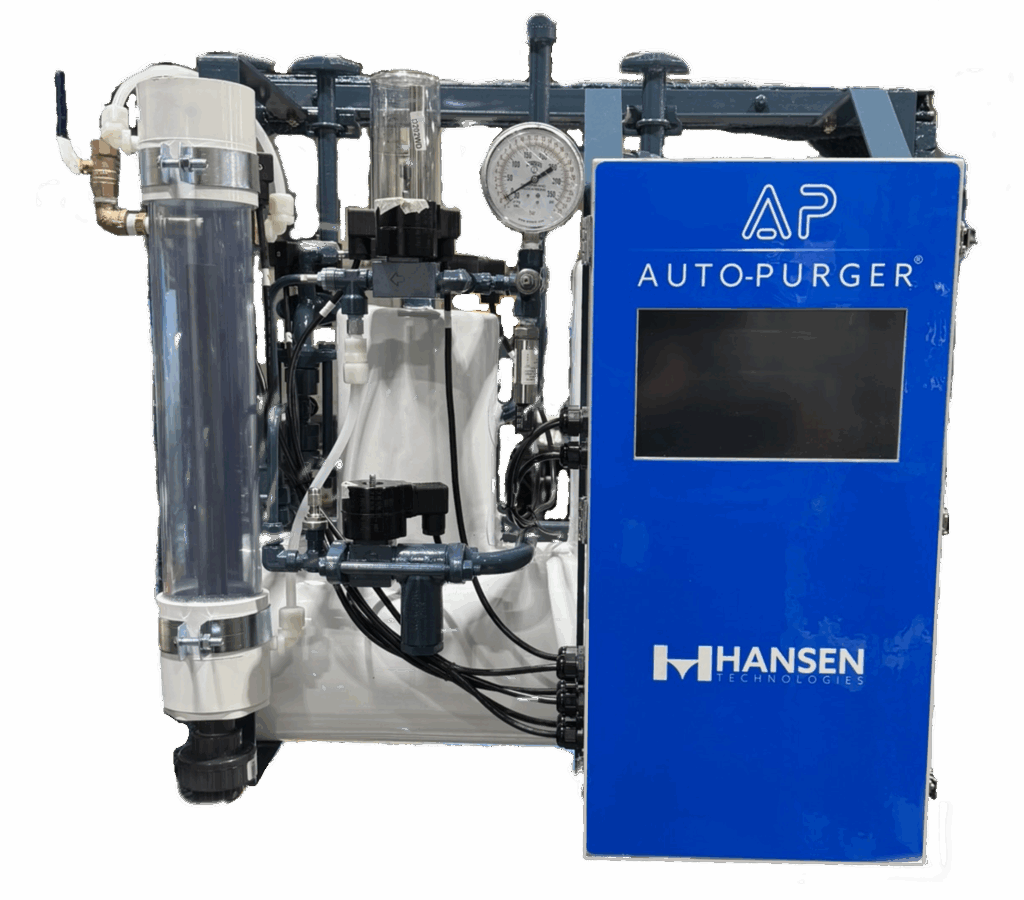

APM | APMF Auto-Purger

A compact version of the original AP Auto-Purger, the APM Auto-Purger is ideal for medium size systems, up to 200 tons (703kW). Like the AP, the APM features automatic start-up with electronic control.

Designed for up to four purge points, an electronic “brain” searches for non-condensible gases in the system and purges at those points where air is present.

The APM includes an automatic water bubbler and comes standard with a NEMA 12, 13 control cabinet.

For use with ammonia or halocarbon refrigeration systems. CE and CSA certified.

Auto-Purger Plus (APP)

The AUTO-PURGER PLUS (APP) is a totally automatic, electronically controlled non-condensible gas (air) and water purger for reducing the energy costs of operating an ammonia refrigeration system.

The APP is shipped preassembled, prewired, insulated, and includes an automatic water bubbler, a relief valve, and an isolation service valve package.

All AUTO-PURGERs are factory tested.

NEAP Mini Auto-Purger

The Non-electric NEAP AUTO-PURGER is ideal for smaller systems up to 100 tons (350 kW) ammonia. The simple design of the NEAP AUTO-PURGER features fully automatic startup, like the other AUTO-PURGERs, and is generally used to purge a single point.

For use with ammonia refrigeration systems.

AP Auto-Purger (Archived)

The original AUTO-PURGER, the AP Auto-Purger has solid-state control and is ideal for larger systems, up to 1500 tons (5275 kW).

The AP has at least two to three times the air removal capacity of any competitive purger, and up to ten times other smaller purgers. With models available to purge up to 8, 16, and 24 points, the AP features automatic startup with electronic control. Purge points can be individually adjusted to meet system requirements. Includes an automatic water bubbler; Optional NEMA 4 rated enclosure also available.

A European model is available that features all-welded construction and conformance to European electrical standards.

The AP is CSA certified. Models are available for use with ammonia or halocarbon refrigeration.

HD101 Defrost Drainer

The HD101 Defrost Drainer, a variation of the HT100 high side float, has an adjustable vent valve bypass to fine-tune individual systems which may experience evaporator defrost gas binding. It is designed as a liquid condensate drain for an evaporator during hot gas defrost. It drains liquid while preventing most hot gas from flowing to the suction line. This process saves energy by eliminating artificial loading of the compressor.

HT Series High Side Floats

These carefully designed and manufactured high-pressure float drain regulators are ideal for metering

high-pressure refrigerant liquid to a lower-pressure

vessel without allowing refrigerant gas to pass. These

self-contained, nonelectrical float drain regulators

provide a simple solution for many applications.

Liquid and gas enter the valve inlet and collect in

the valve body. As the liquid level rises, it lifts the

float ball assembly exposing the slide valve orifice

and metering liquid to the outlet.

Receiver Level Transducer Probes

(For Halocarbon Systems, especially Supermarkets)

Designed to be inserted directly into refrigerant receivers and facilitate the continuous measurement of refrigerant liquid levels.

The following results can be tracked: refrigerant loss detection, refrigerant inventory measurements, warnings of excessive refrigerant levels, and insufficient refrigerant quantity. Factory pre-calibrated and tested with no moving parts to break, jam, or fail.

Horizontal Receiver Probes (SHP) can also be used in short [less than 30˝ (762 mm) insertion] vertical receivers. For vertical receivers 12˝ to 20˝ (305 to 508 mm) diameter (other diameters need special engineering). Maximum insertion length is 69˝ (1752 mm). Output signal 0-5V or 1-6V; 4-20 mA available.

Techni-level™ Level Transducer Probes

These specially-designed Techni-Level Transducer Probes with 4-20 mA output are for refrigerant level control in computer operated industrial and commercial plants.

All transducer electronics are compact, sealed watertight, and located on top of the probe. A 24 Volt DC power input is required. Fifty feet of two-wire cable is included with longer lengths available. An optional 0-100% built-in digital readout is available. Probe active lengths up to 168″ (4267 mm). Level columns are available from Hansen or can be field-fabricated.

For use with ammonia, R22, R134a and other compatible refrigerants.Techni-Level Transducer Probes are an ideal solution for computer-controlled applications on vertical or horizontal vessels, pump accumulators, pilot receivers, and refrigerant loss monitoring.

Vari-Level™ Adjustable Level Control

The Hansen Vari-Level Adjustable Level Control provides excellent level control and monitoring flexibility for industrial and large commercial refrigeration systems. It takes the place of multiple single point level switches on new or existing refrigerant vessels.

This popular, user-friendly, and field-proven system consists of a control unit, and a probe to be inserted in a level column. Control unit models are available with up to five individual level set point relays. Level set points and differentials can be easily set up, and then simply changed by moving knobs when necessary. A built-in level simulator enables the operator to easily check proper operation of control valves, pumps, and alarms at the various set points.

For use with ammonia, R22, R134a and other compatible refrigerants.