HA2A, HA2B Small Pressure Regulators

These small pressure regulators are rugged, compact, and designed for use with refrigerant liquid or vapor. They are suitable for ammonia, R22, R134a, CO2 to 600 psig and other approved refrigerants.

These regulators are commonly-used in small capacity applications or as a pilot valve to operate larger main valve and a non-atmospheric relief to low side (HA2BK). These regulators are furnished with flanges for FPT (Female Pipe Thread, American National Standard, tapered), socket weld or weld neck (to match American Pipe Schedule 40), or ODS (Outside Diameter Sweat) for copper tubing size connections. They have an inlet pressure gauge port.

These regulators can be furnished with close-coupled strainers on the inlet. The HA2BQ and HA2BT are different construction, using the same screw-in control modules (pilots) found on the Hansen HA4AQ and HA4AT pressure regulators.

HA4A Pressure Regulator

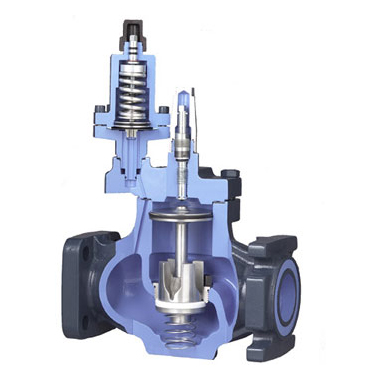

These advanced-design, strong-bodied, precision-

manufactured MODULAR regulators are superior in their

ability to overcome dirt and sticky oil during opening

and tight closing. Models are available for nearly every

control function requirement of industrial ammonia and

commercial halocarbon refrigeration. These regulators

are ideal for cold storage plants, poultry plants, meat

packing, fish processing, freezers, ice plants, breweries,

bottling plants, heat recovery units, petrochemical

plants, pharmaceutical plants, supermarkets, and many

others.

HA4AM

The HA4AM can be ordered “less motor,” which includes control module, cam, and motor-mounting bracket. A three port bonnet with blanking plugs is standard on the HA4AM (up to 4²/100 mm port) so that other pilots can be field installed if required.

The “M” feature can also be ordered with other valve combinations, most commonly the HA4ADM Dual Pressure Regulator with motorized pilot. All material Features for the HA4A modular pressure regulator apply to the HA4AM.

HOTV, HOTW Oil Temperature Valves

A 3-way mixing valve that operates with the use of an internal thermostatic element. As oil is circulated through the screw compressor, it picks up heat from the compressor. The hot oil is circulated past the thermostatic element inside the valve and it is also fed to a heat exchanger, which provides cold oil to the opposite side of the valve.

The thermostatic element modulates the flow of oil from the cold oil port and the hot oil port to maintain a temperature range ±10°F (±5.6°C) of the nominal temperature setting at the outlet.

Rupture Disc Assemblies, Gauges, and Pressure Switches

Hansen rupture disc assemblies (RDAs) are used to indicate which pressure-relief valve has discharged. A pressure-relief valve will re-seat after discharging. However, a rupture disc remains open after bursting. (A rupture disc is not a stand alone safety device.) An installed pressure gauge or switch (required by code) provides a visual or electronic indication that the rupture disc has burst.

Also, rupture disc assemblies provide a hermetic seal to help eliminate any possibility of minute losses of refrigerant via pressure-relief valve seat materials. Hansen rupture disc assemblies are designed with a double-weld construction. There are no gaskets to leak. The rupture disc inside the assembly is patented hermetically welded to the body and mechanically isolated from any pipe stress. A separate body weld seals the assembly. This design helps eliminate internal and external leaks and ensures that the disc will burst at its design pressure.

Pressure Relief Valves

Designed to provide emergency relief from excessive pressure in refrigerant-containing vessels, they are built in strict conformance with ASME Boiler and Pressure Vessel Code requirements for safety relief devices.

Each valve bears the ASME code symbol of certification (UV). Their capacities are rated by the National Board of Boiler and Pressure Vessel Inspectors. These tamper-resistant valves are accurately set and sealed by qualified technicians at the factory.

EZ-SRV Cartridge Relief Valve

Hansen EZ-SRV Cartridge Pressure Relief valves protect refrigeration pressure vessels and other refrigeration system components from excessive pressure. If an abnormally high pressure occurs, the cartridge pressure-relief valve will open to relieve the excess pressure, preventing potential damage to equipment and injury to personnel.

EZ-SRVTM valves are built in strict conformance with both ASME Boiler and Pressure Vessel Code requirements and ISO 4126—Safety Devices for Protection of Excessive Pressure. Each valve bears the ASME code symbol of certi cation (UV) and CE mark. Valve capacities are rated by the National Board of Boiler and Pressure Vessel Inspectors (NB).

PXV & PXVW Expansion Valves

The Hansen PXV and PXVW are pulse modulating liquid refrigerant expansion valves. The PXV uses a specially designed, high-cycle, long life, solenoid operator. A sophisticated 4-20 mA input signal is used to monitor the liquid flow to the system. Unlike traditional TXVs, the pulse design eliminates the need to maintain minimum pressure differential. Low and varying liquid feed pressures (head pressure) are compensated by the basic variable valve operation. It is suitable for use with ammonia and most common refrigerants.

The unique PXVW60 body has an integral 100 mesh (150 micron) strainer screen and features direct weld assembly, eliminating flange gasket leak potential. In addition, the PXVW valve has an adjustable, integral hand-expansion plug to regulate the flow from 15 to 60 nominal tons of ammonia. Consult the factory for PXVW halocarbon capacities.

Butt Weld Shut-Off Valve

Hansen low pressure drop refrigerant shut-off valves are designed to be butt-welded directly to steel piping, thereby eliminating potential leaky flanges or threaded joints and simplifying installation. Cast steel bodies are lightweight, yet have substantial wall thickness to overcome corrosion potential.

The cast steel body is rigid, reducing the potential for seat leakage due to flexing of the valve body under abnormal conditions. The “heart” of Hansen shut-off valves is the patented no-leak seal-plus-stempacking design. This seal design is used exclusively on Hansen shut-off valves and virtually eliminates stem seal leakage.

Socket Weld Shut-Off Valve

The advanced design and materials of the Hansen Steel Body Socket Weld Refrigerant Valves make them stronger and far superior to other commonly available products. This is especially true in regard to leakage from seats, stems, bonnets, and piping connections.

Socket weld steel bodies permit these valves to be quickly and easily welded directly into piping without the inconvenience of pipe threading or using bulkier iron-flanged valves with socket weld steel flanges requiring bolts, nuts, and gaskets.

Compared to butt weld valves, the Hansen socket weld bodies allow quicker welding, easier pipe alignment, and cleaner pipe and valve interiors.