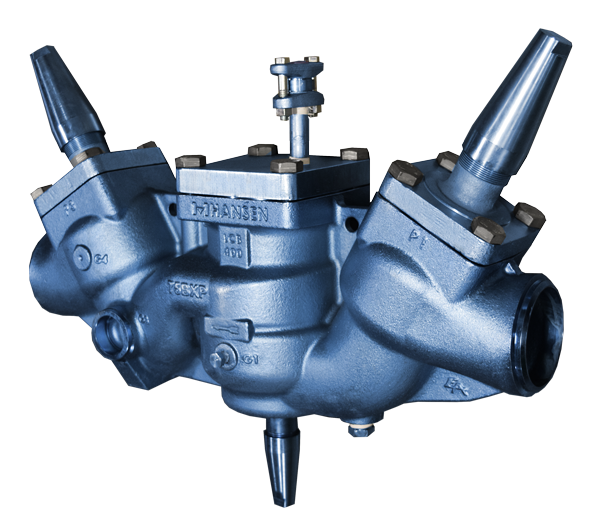

Installed cost savings is a huge advantage of the MVP valve. Faster installation, less pipe cutting, welding assembly time, insulation, and freight equal reduced costs. In addition, the compact valve body saves installation space and valve group weight.

MVP20 – MVP50 valves includes five pressure gauge ports to measure pressure at multiple locations on the valve, as well as a ¾˝ NPT side connection for pilot line to gas-powered suction valve. MVP65 – MVP100 valves include 3 pressure gauge ports as well as a customizable side port feature for use with defrost condensate piping.

½˝–4˝ (13mm-100mm)

FPT (MVP13 only): ½˝–¾˝ (13mm–20mm)

Socket Weld: ½˝–2˝ (13mm–50mm)

Butt Weld: ½˝–4˝ (13mm–100mm)

ODS: 5⁄8˝–25⁄8˝ (16mm–67mm)