Hansen rupture disc assemblies (RDAs) are used to indicate which pressure-relief valve has discharged. A pressure-relief valve will re-seat after discharging. However, a rupture disc remains open after bursting. (A rupture disc is not a stand alone safety device.) An installed pressure gauge or switch (required by code) provides a visual or electronic indication that the rupture disc has burst.

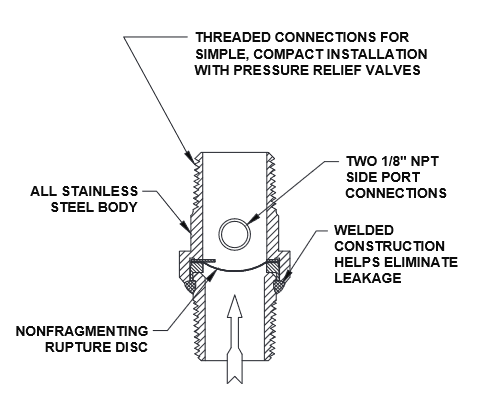

Also, rupture disc assemblies provide a hermetic seal to help eliminate any possibility of minute losses of refrigerant via pressure-relief valve seat materials. Hansen rupture disc assemblies are designed with a double-weld construction. There are no gaskets to leak. The rupture disc inside the assembly is patented hermetically welded to the body and mechanically isolated from any pipe stress. A separate body weld seals the assembly. This design helps eliminate internal and external leaks and ensures that the disc will burst at its design pressure.